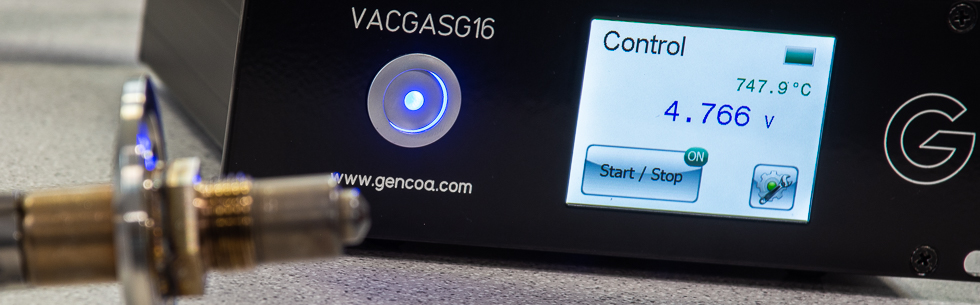

VACGAS-G16

The Gencoa VACGAS-G16 sensing unit provides an industrially robust means to sense elements of group 16 - The Chalcogens. The important species in group 16 from a vacuum processing point of view are oxygen, sulphur and selenium.

The sensing method uses a zirconium oxide ceramic (zirconia - lambda sensor) and is based on a solid-state electrochemical fuel cell called the Nernst cell. Its two electrodes provide an output voltage corresponding to the quantity of gas in the vacuum. The VACGAS-G16 combines feedback control of the sensor temperature with gas correction to provide the O2 level as a precise partial pressure.

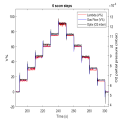

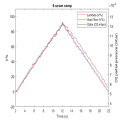

The basic technique is used in automotive engines to sample oxygen levels and ensure efficient combustion. Whilst Lambda sensors have been employed for many years to sense oxygen in vacuum, the speed and accuracy of the signal has not been as good as optical and mass spectrometry methods. The Gencoa VACGAS-G16 matches the gas outputs from RGA and optical spectrum methods with better sensitivity compared to differentially pumped RGA’s (less noise).

This signal accuracy is combined with the inherent robustness and low cost of the method when compared with other vacuum gas sensors. The sensor head has an infinite life and the control ensures signal stability and accuracy. The sensor can be located on the chamber wall (KF40 as standard), or inserted into the vacuum chamber as part of a sealed assembly. There are no sensitive electronics, hence the sensor won’t fail.

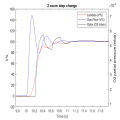

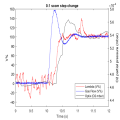

The limitations of the Nernst Cell means that for a large gas change, it can take 5 seconds to respond to the ultimate signal level, which compares to 3 seconds for a differentially pumped RGA. Optical methods based upon OPTIX are much faster (see below), 0.1 to 2 sec depending upon integration time.

VACGAS-G16: a key addition to vacuum system data tracking

A vacuum gauge provides essential system information and knowing the level of oxygen in a vacuum chamber has multiple other uses:

- Basic health of the vacuum chamber and process – identify contamination or problems

- Quality control data for each process cycle – track product & process quality

- Monitor pump-down and system process readiness

- Use the oxygen signal to adjust mass flow control of O2 entering the chamber

- Fast feedback control to increase deposition rates – combine the VACGAS-G16 with a speedflo controller

- Control uniformity by local sensing and adjust of O2 levels in the process zone

Potential process types

- Sputtering, electron beam and thermal vacuum coating methods

- Plasma and thermally based oxidation / surface treatment

- Solar cell manufacturing involving sulphur or selenium gases

- Nitriding plants during pre-oxidation, post-oxidation, oxynitriding

- On-line oxygen monitor for use with vacuum packaging systems

Specifications

- Display 24 x 32mm touch screen

- Warm-up time , 20 mins

- Max pressure: 1 mbar

- Min. measuring pressure: 10 -7 mbar

- Helium leak rate < 10 -8 mbar l/s

- Reaction time: 5 sec zero to full scale

- Measuring sensitivity: <5 ppm

- Temperature at KF flange: max. 185 °C

- Power supply: 24 V DC / >1.5 A

- Mechanical connection: KF40 vacuum-flange – internal or external with variable connection cables lengths

- Output: DB9 connector, RS 232 communication (0-10V or partial pressure (Pa, mbar or mTorr))

Accessories

- different KF or CF vacuum flange sizes

- speedflo reactive gas controllers (3 and 8 channel)

- pulsed S and Se effusion cells

Associated gas sensing products

Optix multi-gas plasma sensor and end-point detection

Gallery

Downloads

Related Applications

Upcoming Events

- 8-10 April 2026 - 5th Heat Treatment and HIP User Conference

- 14-16 April 2026 - Heat Treat Mexico

- 25-30 April 2026 - SVC Techcon

- 19-21 May 2026 - R2R Conference USA

- View full list >