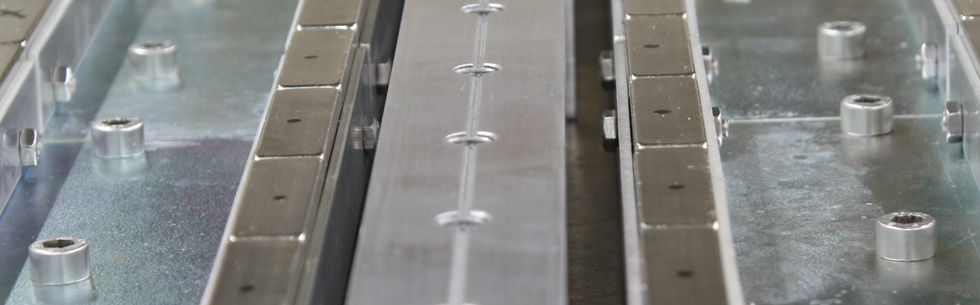

Retrofit magnetics

In some cases where it is not necessary or desirable to replace a complete magnetron cathode, it is possible for Gencoa to provide a replacement magnetic system to fit into the existing cathode body. This is a cost-effective method of upgrading the performance of the current system.

In nearly all cases it is possible to fit our standard balanced (SW) or unbalanced (PP) magnetic systems. In 70% of cases it is possible to fit our high yield (HY) type magnetics.

The possible reasons to replace magnets are include the following:

- Defective magnets

- Corrosion of magnets located in water (very common)

- Over-heating and degaussing of the magnets

- To increase target utilization

- To increase magnetic field strength for low pressure/voltage or magnetic material sputtering

- To improve coating uniformity in both circular and rectangular geometries

- To enhance plasma reactivity and energy by unbalancing the magnetic field

- To reduce arcing by avoiding closed magnetic field interactions with system anodes

- To achieve cleaner targets, especially in reactive sputtering

Contact [email protected] with details of your current cathodes and required magnetics to discuss the available options for a planar magnetron retrofit.

Gallery

Downloads

Contact Gencoa

To contact Gencoa at our Liverpool headquarters, click for contact details.

For details of international representatives, refer to our list of worldwide contacts.