Magnetic Options

Effective magnetron sputtering relies on an adequate magnetic field design for a optimal process operation. Gencoa offers a wide variety of magnetic options for all sputtering applications.

Balanced

A balanced (SW) source contains a conventional type of 2 pole magnetic array which generates an efficient magnetic trap over the target surface and minimizes electron and plasma loss from the source, avoiding excessive plasma bombardment onto the substrate.

Unbalanced

The unbalanced (PP) magnetic array changes the shape of the magnetic field to allow release of some of the plasma electron towards the substrate to provide ion assistance for the coating process.

High Yield

The high yield (HY) optional magnetic array increases the target utilization from typically 20%-25% for standard 2 pole magnetics to 35-50%. The enhanced target use is created by additional magnetic poles within the magnetic system to deform and flatten the magnetic field structure over the target surface.

High Uniformity

Based upon a specific target size, substrate size and target to substrate separation, a magnetic array can be designed to give a specified uniformity on the substrate. The coating uniformity is simulated based upon the magnetic field shape.

RF

RF sputtering is usually applied to insulating or low electrically conductive targets. In RF sputtering the inherent enhanced ionization of the plasma can result in very low target voltage which may result in low rates. An adequate RF cathode design will include a specific magnetic field design, which will affect the sputtering and process yield effectiveness, including uniformity and coating rates.

High Strength

High strength magnetics deliver a magnetic field strengh of 500-1000G on the target surface, and are suited to applications such as ferromagnetic target sputtering, low pressure sputtering and low voltage sputtering.

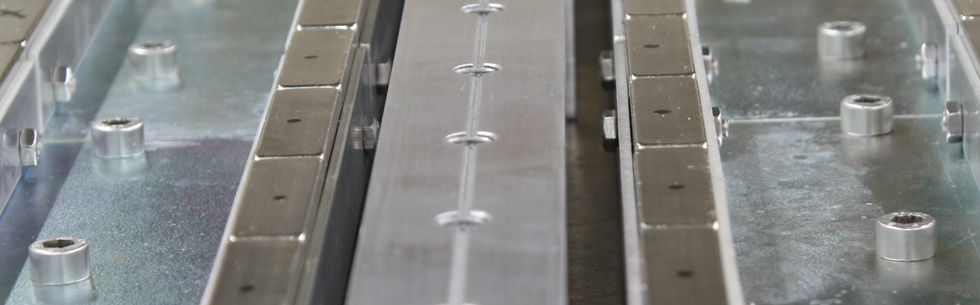

LOOP

The LOOP magnetic and target design overcomes the problem of sputtering ferromagnetic target materials. This option can sputter Ni, Co, Fe, etc. targets of typically 2-4 times the thickness of conventional very high strength magnetrons with over 30% target yield increase compared to a standard target. In LOOP magnetics, the target itself becomes and active part of the magnetic array and magnetic design.

Metallizer

Metallizer magnetics deliver high target utilization for sputtering of non-magnetic materials, while extending process times for production.

Full face erosion

FFE magnetics improve target erosion and uniformity through motor driven dynamic plasma scanning which allows the whole target surface to be sputtered, maximizing erosion at the outer edge of the target. There is no uniformity drift with target life.

Vtech/VT-ER

The unique VTech magnetics allows the variables of magnetic field properties of the source to be adjusted, creating the following effects: variable degree of unbalance, to adjust the electron release and levels of ion bombardment of the growing film; variation of balance, to reduce the additional energy input to the growing film and substrate and produce low bombardment conditions; variation of the magnetic field strength in order to adjust the discharge voltage and current. A new variation controlling the degree of balanced/unbalanced is achieved through VT-ER externally actuated magnetics.

Downloads

Gencoa Newsletter

Signup to Gencoa's newsletter to receive exhibition news and updates on new product releases.

Gencoa

Gencoa